Yarab A |Updated on: December 14, 2022

- What are inventory carrying costs?

- What are the types of inventory?

- What are the components of inventory carrying costs?

- How to calculate inventory carrying costs?

- What do high holding costs mean for small businesses?

- 4 smart ways to bring down your business carrying costs

- How to maintain the ideal inventory stock level balance?

In a competitive market, a company has to be very careful to watch for and curtail unnecessary expenses. Inventory carrying cost is a necessary expense for any company that stores purchased raw material and manufactured goods. It is essential for a business to maintain a healthy balance between carrying enough inventory while not carrying too much. If there is excess inventory, over time it inflates the inventory carrying cost.

What are inventory carrying costs?

Inventory carrying costs are also called holding costs. Inventory carrying cost is the expense towards holding and maintaining inventory over a period of time. Ideally, this cost should be within 15% to 30% of the company’s total inventory value. Some of the expenses that are categorized as holding costs are warehousing, insurance, employee salaries, and taxes. The amount of inventory that is required is different from industry to industry. Even within the same industry, a smaller scale business would have a lower inventory than a larger one. The amount that is incurred towards holding the inventory also varies between industries and company sizes.

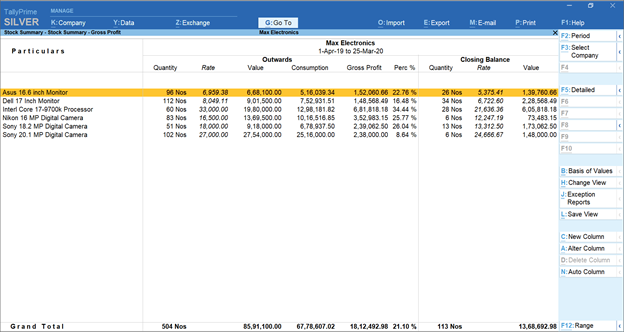

Stock Summary report From TallyPrime

What are the types of inventory?

The items that are in inventory are very dependent on the type of industry. But generally, inventory can be classified as

- Raw materials

Every manufacturing company will need to purchase the raw materials that are required for the manufacture of goods. The adequate supply and stock of raw materials are critical to the entire production process. The raw materials can be of two types; direct resources and indirect resources. For example, the main ingredient for your manufacturing process may be sheets of metal. But you may also need to stock the stickers that you use on the finished metal product. Raw materials can be purchased from a vendor or produced by the manufacturer itself. For example, a dairy farm may produce the milk that they use to make ice cream.

| What is Inventory Optimisation – Steps to Improve Inventory Process | Quick Tips for Buying the Best Inventory Management Software |

- Work in progress

When you have items in ongoing production, the intermediate works in progress need to be stored. For example, if you manufacture cars, you would individually ready sections of cars which would have to be stored. The individual sections would then be assembled into a completed car. So, storage of the works in progress is also counted as inventory.

- Finished goods

After going through the production process, the company will have stock of its finished goods. These goods will be stored and then shipped to stockists or the supply chain. Finished goods inventory also costs money to store. A company should aim to make this finished goods inventory storage time as short as possible to save on the inventory costs of storing them.

- Maintenance, repair and, operating inventory (MRO)

A business needs to store items that are related to the maintenance, repair, and operation of its manufacturing process. These items would be lubricants, spare parts, cleaning supplies, and the tools that would be required to maintain and repair the machinery.

What are the components of inventory carrying costs?

The different components of holding costs are:

- Capital costs

A company invests money in the purchase of inventory. Capital cost is the investment made into the fixed assets as well as the interest on them. This is one of the most significant components of inventory value. It is usually indicated as a percentage. So, if your capital cost is 30% of an inventory value of 50,000, the capital cost is 15,000.

- Storage space costs

Storage of inventory requires space as well as other costs towards the storage conditions. Storage space costs include the money that is spent in organizing and storing stock. The most common cost under this category is the cost of renting a warehouse. If the stock has to be maintained at an ideal temperature, you would also spend towards heating or air conditioning of this storage space. You will also incur utility expenses towards maintaining the warehousing facility.

- Inventory service costs

Inventory needs to be properly sorted, organized, and managed. Companies usually invest in an inventory management system to handle this. Using intelligent business management software such as TallyPrime helps seamlessly integrate the inventory management process with accounting and sales. There is also the additional expense of taxes, insurance, and other expenses as mandated by the authorities.

- Inventory risk costs

Holding items in inventory has an inherent risk. There are different uncertainties that you may face in storing items such as:

-

- Shrinkage or loss caused to the inventory item before sale to a customer

- Depreciation

- Inventory becoming obsolete because of being past its expiry date

How to calculate inventory carrying costs?

There are two methods by which you can calculate the inventory holding costs for your business:

Method 1

This is a very rough and approximate method of estimating the inventory holding cost of a company.

Inventory Carrying Cost = Total Annual Inventory Value/4

So, for example, the annual inventory value of a company is 100,000.

Inventory Carrying Cost = 100,000/4= 25,000

Method 2

This is a more precise method of calculating the inventory carrying costs.

Inventory Carrying Costs = (Inventory Holding Sum / Total Annual Inventory Value) x 100

We can calculate the inventory holding sum as the total of all the inventory costs, namely; capital, storage, services, and risks.

For example:

A company that has a 100,000 inventory value for which the various costs are

Capital: 10,000

Storage: 2,000

Service: 2,500

Inventory Risk Costs: 3,500

The inventory holding sum is 10,000 + 2,000 + 2,500 + 3,500 = 18,000

Using the formula,

Inventory Carrying Costs = (Inventory Holding Sum / Total Annual Inventory Value) x 100

Inventory Carrying Cost = 18,000/100,000 x 100 = 18%

What do high holding costs mean for small businesses?

It is important for a company to have adequate inventory for multiple reasons. Generous and timely availability of raw materials and items needed for MRO keeps the manufacturing process supplied with material resources. When there is enough inventory of finished goods, customers get supplied quickly and this increases customer satisfaction. Having enough supply of finished goods will also be ideal to capitalize on high demand periods. However, higher inventory carrying costs could also be disadvantageous for the following reasons

- Increased overheads impacting cash flow

- Higher storage costs

- Higher insurance p[remiums

- Higher risk of obsolescence and depreciation

4 smart ways to bring down your business carrying costs

It is in the best interest of the company to keep its inventory carrying costs as low as possible. Some of the strategies that can be used are:

- Optimize and lower inventory holding

Ideally, a company would have just enough stock in inventory. It should be at the ideal balance between overstocking and inadequate stocking. At no point should the stock be inadequate or overstocked. Inventory turnover should also factor in sales patterns and compensate adequately. Inventory levels should be different for items that sell out fast and those that take longer. Raw materials that are harder or slower to procure should have a higher level of inventory.

- Upgrade warehousing

Choose the best warehouse not just for the storage space. A warehouse that is well organized and compact makes it quicker and easier to locate items in. An efficient warehouse saves you money by lowering insurance premiums, tax costs, and depreciation.

- Automate inventory management

Managing inventory is cumbersome when done manually. Using technology such as TallyPrime to optimize and manage inventory makes inventory management easy and quick. TallyPrime allows you to update, review and use inventory information in real-time. Inventory management software that tracks items, generates all the relevant reports, and updates stocks in real-time, gives you an accurate picture of your inventory. The ability to analyse reports helps you study inventory patterns and data to optimize your inventory holding and reduce the holding cost.

- Eliminate deadstock

Deadstock is troublesome as it costs money to store and locks up capital. Deadstock can be handled by

-

- Checking return and refund policies on the item and returning it if possible.

- Donating it and getting tax benefits

- Giving the item away as a freebie

- Having a stock clearance sale

How to maintain the ideal inventory stock level balance?

When you manage inventory intelligently, your inventory holding cost is optimized. This frees up money that would otherwise be locked in the stocks and wasted on inventory holding costs. Using an inventory management tool such as TallyPrime saves you time, effort and money spent on inventory. The analytical and reporting tools will help you intelligently make decisions to reduce inventory holding costs. Reducing inventory holding costs will make a difference to the bottom line of the business.

Read more:

Latest Blogs

Nuts & Bolts of Tally Filesystem: RangeTree

A Comprehensive Guide to UDYAM Payment Rules

UDYAM MSME Registration: Financial Boon for Small Businesses

Understanding UDYAM Registration: A Comprehensive Guide

MSME Payment Rule Changes from 1st April 2024: A Quick Guide

Are Your Suppliers Registered Under MSME (UDYAM)?